If the reflector is not flat enough, however, the incident light will not flow parallel. The radius of curvature for the convex or concave surface can now be read off the scale on the objective correction ring.”įundamental to the working of the autocollimator is the assumption that the emitted light and the incident light will be parallel to each other. As shown in Figure 4, the autocollimator is placed so that it is facing the convex or concave surface and the observer turns the objective correction ring so that the crosshair image produced by the reflection is clearly visible. This function allows measurement of the radius of curvature for convex and concave surfaces. “The light rays can be made to diverge or converge by turning the objective correction ring. Matsumoto explains the strengths of the Autocollimator 6B and 6D.

Measuring the radius of curvature for convex and concave surfaces While the stand is moved up and down, the straightness is measured to check that it meets precision standards. In the photograph, an Autocollimator 6B is being used to check the stand of a ShuttlePix digital microscope. Nikon uses both the Autocollimator 6B and Autocollimator 6D for various in-house checks. Conversely, the application for this could be the estimation of external force based on the level of deflection.

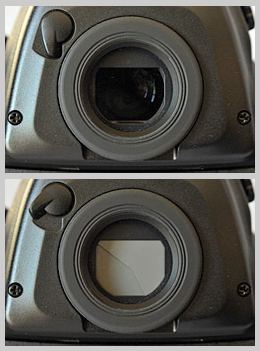

Alternately blocking the optical path from the surface to be measured and the standard reflecting surface makes it possible to determine which surface the crosshair image is originating from.įigure 3 illustrates the method for measuring the deflection in an elastic component by mounting a reflector on it. Two crosshair images-one from the reflecting surface to be measured and the other from the standard reflecting surface-are visible at the same time, and the difference between them is read off on the autocollimator. Figure 2 illustrates the method for measuring the degree of parallelism between two flat surfaces.

0 kommentar(er)

0 kommentar(er)